Built to Last

Excellence

Rigorous Quality Control System

Premium-Grade Raw Materials

Premium-Grade Raw Materials

Continuous Monitoring

Continuous Monitoring

PRIMEBOND

Excellence in Aluminum Composite Panels

Our US-based composite panels are manufactured using advanced technology. They are strong while remaining lightweight. These ideal, aesthetic, and durable panels are weather-resistant and represent the future of architecture.

Redefining Quality

Elevating Standards

Products

Innovative & Reliable

ACP Solutions

PRIMEBOND PE

The PrimBond composite aluminum PE panels are suitable for both interior and exterior applications. These panels are made of 100% low-density polyethylene (LDPE), which enhances workability and makes them an excellent choice for cladding and decoration. Given their class E and flammable properties, they should be used in fire safety areas. PE possesses strong and manageable material.

The PE panels have a thickness of 4mm to 6mm and a density of 1.2-1.3 g/cm³, with flexible handling and widths up to 1500mm. They can be shaped and designed in various ways.

PRIMEBOND A2

A2 core comprises 90% minerals and features a non-combustible class A2-s1 d0 material that does not contribute to a fire, produces no flaming droplets, and minimizes heat-release smoke. Its 0.5 mm thick aluminum skin showcases durability and strength and is suitable for strictly regulated buildings.

The A2 is 1220 to 1500 mm wide, 6000 mm long, and has a high density of 1.8 to 1.9 g/cm³, making it versatile and stable for external construction while also being aesthetically pleasing.

PRIMEBOND FR

Regarding fire safety in high-rise buildings, FR core composite panels are the top priority. They are made of 70% minerals and 30% PE, making them fire-resistant. They have a B-s1,d0 rating, producing less smoke with no flame and being safer than PE core panels. The 0.5mm thick aluminum makes them durable and strong.

With a density of 1.5-1.6 g/cm³ and a panel thickness of 4mm to 6mm, FR is best suited for external facades. Its widths of 1220, 1250, and up to 1500 mm, along with a length of 6000 mm, are suitable for efficient coverage in both commercial and residential buildings.

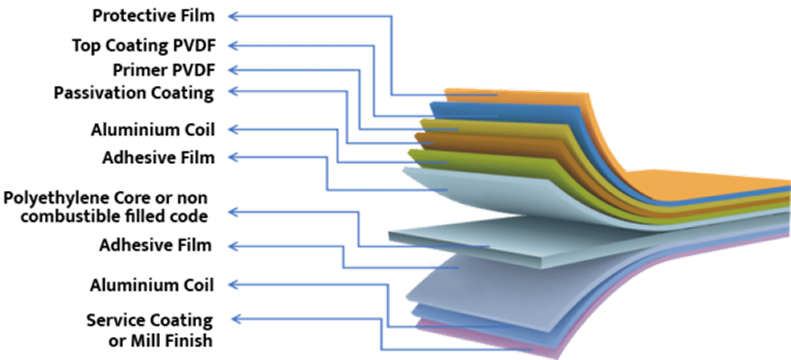

Composition

Aluminum Composite Panel.

The Surprising Benefits of Aluminium Panels for Construction

Aluminum composite panels have become a top priority in the construction, and they have many benefits. They are:

- Duarbel

- Suitable in extreme temperatures and severe weather

- Useable for both interior and exterior

- Easy to handle and install due to lightweight

- Comfortable and insulated

- Eco friendly

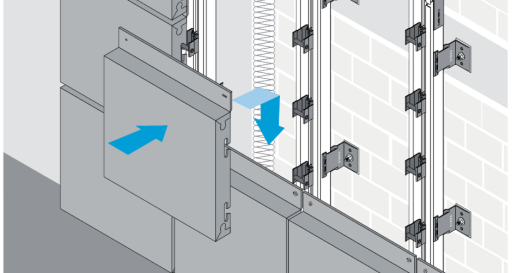

Flexible structure and innovative design of the panels

The aluminium panels are versatile in design and flexible in their structure. From curved to angular, their innovation is superior and stunning. They are unique in form and durable in structure. A perfect symbol of contemporary architecture.

Uses of Aluminum Panels in Modern Construction

Modern construction is incomplete without aluminium panels. These are the top choices of contemporary builders due to their durability and style and are used in roofing, cladding, and interior designs. They give a unique appearance with various colour combinations to the buildings.

Materials

Premium Raw Materials

Aluminum Alloy

Aluminum alloy is unique because it is made with various elements. It is also lightweight, so it is used in many projects.

- It is strong but lighter than steel, so easy to handle.

- The aluminum alloy is weather-resistant.

- Aluminum alloy is not heavy but yet strong.

- Due to its flexibility, it is easy to mold and suitable for many designs.

- They are environmentally friendly and recyclable.

- Heat and electricity can be easily transferred to the alloy.

Properties

Coating

At the surface, the coating plays many functions, such as protection and beauty.

- The coating protects the inner material from weather, rust and other damages.

- With the color combination, the coating makes the surface more attractive.

- It comes in various types, including some that are waterproof and fire-resistant.

- Cleaning is easy.

- It stays for longer without replacement.

- The coating shines and enhances the natural light for the buildings.

Properties

Adhesive Lamination Film

Adhesive lamination film is a process that involves joining different materials to protect various surfaces.

- It works like a strong glue to join different materials.

- Prolonging the life of the surfaces protects them from weather damage.

- With a glossy effect, it improves the appearance of the laminated object.

- The lamination film is not only durable but also flexible.

- The adhesive lamination is used in packaging, signage, and construction.

- Easily applicable in different places.

Product Specifications

Blog

Insights & Innovations in ACP

- by km@code-x.co

- 04 Jan 2022

Utilization of Titanium In Industrie

Utilization of Titanium In Industrie

- by km@code-x.co

- 29 Dec 2021

The Role Of The CNC Machine Operator

The Role Of The CNC Machine Operator

- by km@code-x.co

- 29 Dec 2021

The Various Industries That Take Advantage

The Various Industries That Take Advantage

- by km@code-x.co

- 29 Dec 2021

Construction Industry Heading Upright Using

Construction Industry Heading Upright Using

- by km@code-x.co

- 11 Nov 2021

Key headlines for the best pharmaceutical

Key headlines for the best pharmaceutical

- by km@code-x.co

- 11 Nov 2021